The benefits and manufacturing process of PCB prototype

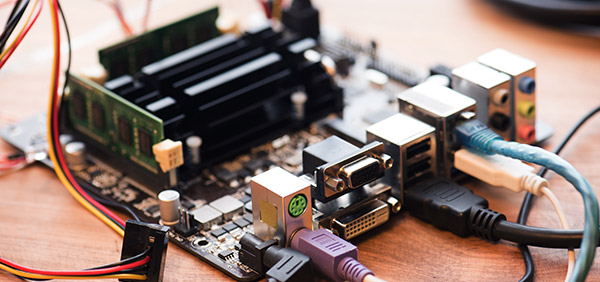

In order to verify the construction and design of a printed circuit board, a PCB prototype is made. Also known as PCB sample, PCB prototype is the backbone of any PCB project. In order to ensure that the PCB design will work and function properly, high tech engineers and PCB hobbyists need to test their device by using prototype printed circuit boards before production begins. In order to ensure the reliability of your PCB Gerber data and manufacturability of circuit board design, reviewing your PCB sample is necessary. A basic sample of a printed circuit board and commonly used in modern electronics, PCB prototype offers many benefits. The primary benefit of PCB sample is testing the circuit board for possible performance flaws. Following are some of the benefits of PCB sample or prototype.

Easy to repair

Checking printed circuit board prototypes for renovations and repairs is easy due to their size and dimensions. You can quickly analyze board performance parameters. When components are well arranged, easily visible and compact, understanding their functions and their arrangements within the circuit becomes easy. Furthermore, you can easily follow and trace electricity flow paths. As they possess the three aforementioned qualities, prototype printed circuit boards are extremely useful.

Well connected and self integrated

As they are held fast on the board, the parts of prototype printed circuit board do not roll off the surface, get lost or get disturbed by movement. One of the neatest and most well managed circuits, prototypes make it easy to find various components. Furthermore, it is easy to install these circuits on smaller electronic devices because their resistors, capacitors, and wires do not sway. Finally, they eliminate the risk of short circuits or charge leakage.

Suitable for diverse equipment

A prototype printed circuit board is suitable for installation in a number of devices due to its dimensions and structure. You can easily fit them into electronic devices of different functions and sizes. Furthermore, an internal mechanism of the prototype makes a device small and easy to carry and use.

A sample printed circuit board has many benefits. However, its manufacturing process is complicated.

Following are the steps involved in the manufacturing process of sample printed circuit boards:

• The first step is sticking together thermosetting resin and laminate layers. This step is carried out under intense pressure and heat. The laminate is etched with electricity flows pathways once it’s ready.

• In order to make a good conductor, the laminates are copper plated.

• Using methods such as silkscreen printing and photoengraving, the residual metal is scrapped off

• Based on the device being designed, circuit patterns are etched and components are assembled.

• For increased effectiveness, carbon ink printing and laser drilling are applied

The brainpower behind electronic devices such as printers, answering machines, computers, digital cameras and microwaves, printed circuit board prototypes offer many benefits. Therefore, using them before production begins is recommended.