Electronic Board Repair Service

Printed circuit boards and an electronic board repair service go hand in hand as everything is automated nowadays and issues can occur. It pays to have a repair service which you can trust and which offers you competitive packages and rates every time you need to give them a call. There are a few tips and tricks regarding choosing a repair service which you should bear in mind so you get the best deal.

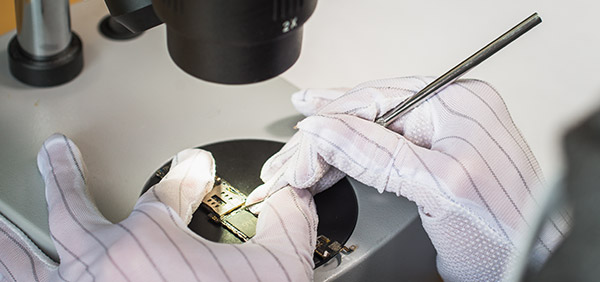

Technicians

Make sure that the company you choose to put in your contact list are trained and qualified professionals with at least a few years of experience under their belts. If the technician operates alone you can check the Better Business Bureau for registered complaints or rather the lack of them. Furthermore, make sure they are IPC Certified as this is the most used electrical standard and is a test of their skill and flexibility when it comes to repairing printed circuits. Many companies offer training every day so that their electricians and technicians can keep up with newer technologies entering the market.

Compatibility And Quality

You should be getting compatible components for your board according to manufacturer’s instructions as cheaper alternatives can lessen the lifespan of the electronic device. Not only should the work be of good quality but the replaced components should also be the best possible quality available.

Monitoring And Rework

It is not enough for a technician to just replace or repair components and then leave you to it. They need to provide warranty for those components and also some sort of reworking and monitoring process to make sure those parts are working to their full capability. Assistance after the initial job should be free or at a fraction of the initial rates.

Scale Of Services

The repair company you choose should offer a wide range of services from replacements to repairs and they should have viable suppliers for most major brands. In a nutshell they should have the available expertise to repair single sided circuit boards, double sided ones and multi-layered boards. Modification is also an important part of bringing your printed circuit up to mark. Sometimes the board is not entirely defective but simply heats up too frequently or is not adequate for the load it is receiving. In this case the technician will have to modify some of the components to upgrade the board to perform better.

Testimonials or Client References

While saving money is a very attractive prospect you want to opt for a company that is relatively well known and is open about their past clients and testimonials. More importantly, these testimonials should check out. If possible contact their previous clients to get a better idea of their operating costs and general demeanor. You can also email the repair service to provide testimonials if they are not available on their website. Opt for word of mouth recommendations as often as possible as there is less chance of going wrong. Last but not least, remember that it costs a lot less to repair a circuit board than to buy a new one so a quality repair service is very beneficial.