Air Conditioner Circuit Board Repair

When professionals talk about air conditioner circuit board repair they are usually referring to problems arising in something called the ‘control board’ in an ac. This control board carries out all functions of the air conditioner and it can sometimes get damaged due to overheating, electricity fluctuation or just the passage of time.

When the ac is not turning on or there is smoke arising from it to suggest a blown fuse then you should check a number of things to ascertain the exact area where repair needs to be done.

Temperature Control

A sensor bulb is used to give signals to the electrical circuit which in turn determines the flow of air. Try using the ac with an energy saver and check if the fan turns on or not. When the air conditioner changes temperatures the contacts in the circuit board should emit a clicking noise. The absence of the clicking noise means that the circuit board has been damaged.

Internal Fuse

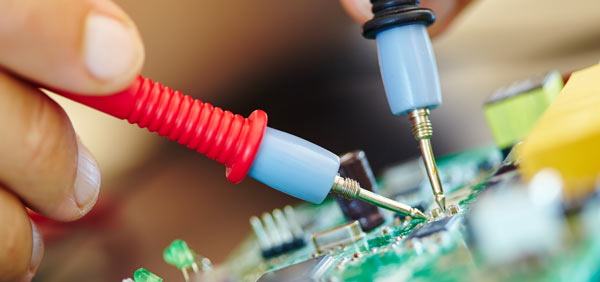

The second thing you should consider is the internal fuse that is found inside most air conditioners. Fuses are generally removable and the smell emanating from it will indicate that you need to replace it. A multi-meter can also be used and it is a device which detects blown fuses among other things. When you are replacing the fuse make sure you follow manufacturer’s instructions and use the right type.

Thermistor

In ACs governed by printed circuit boards a thermistor device is a must. It is found at the front of the Ac’s evaporator and it can determine the state of the printed board.

Power Cord

If you have checked all the other variables, simply inspect the power cord because the simple problem of a defect or a tear there means the AC is not getting enough power to function properly. This in turn can blow out fuses or damage the circuit board due to a ‘fluctuation.’ Your power plug may also be to blame and may need to be replaced.

Reasons Why Hiring An Expert Is A Good Idea

• You can often get competitive pricing with a professional and they will give you additional services like servicing your AC and checking for other issues which might bother you in the near future so you can get them fixed in one go.

• Sometimes the circuit board needs to be replaced and while that is a costly ordeal, you are likely to get a warranty on your new board which you may not have had on your old one since manufacturers try to dodge that risk.

• If you attempt repair work yourself you may do temporary fixer-uppers which will end badly while an experienced technician might be able to tell right away that what is needed is a circuit board replacement or a replacement of several damaged traces which might be hard to detect for a layman.

• An expert will almost never use incompatible parts for air conditioner circuit board repair as they are trained otherwise. This ensures your Ac gets a longer useful life and will require less repair in the years to come.