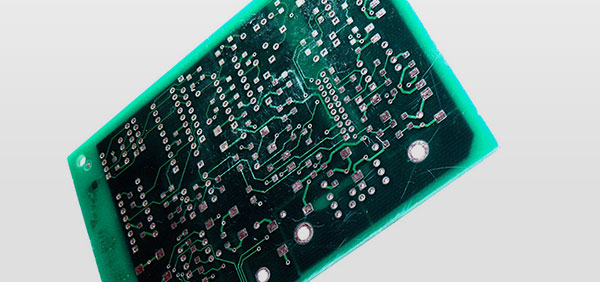

Cheap PCB Prototype

Without a PCB prototype, verifying and designing a printed circuit board is not possible. The backbone of any PCB project, PCB prototype ensures that the PCB design will work and function properly. Before production of PCBs begins, prototype printed circuit boards are tested by high tech engineers and other relevant people. Reviewing your PCB prototype is necessary if you want to ensure the reliability of your PCB Gerber data and manufacturability of circuit board design. There are many benefits of using printed circuit board prototypes. Testing the circuit board for possible performance flaws is the biggest one. Other benefits of prototype printed circuit boards include:

- Easy to repair circuit boards

- Well connected and self-integrated

- Suitable for diverse equipment

Printed circuit board prototypes offer many benefits and are the brainpower behind electronic devices such as printers, answering machines, computers, digital cameras, and microwaves. This is the reason using them before production is recommended. Contrary to the popular belief, creating a Printed circuit board prototype can be easy and low cost. Doing it yourself is the way to go. The two major benefits of manufacturing this cheap PCB prototype include:

- Greater consistency

- Easy mass production

Additionally, you can use cheap PCB prototype to substantially increase the circuit and component density. Other benefits of cheap PCB prototype include:

- Adding your own logo to designs

- Running single traces all around the board

- Reproduction

- Obtaining a well-finished and tidy circuit board rather than a nest of jumper wires

Let’s now take a look at how you can create a quality cheap PCB prototype. The first step in creating cheap printed circuit board is making a board layout. Start by finding designs schematics for your circuit. You can do this with the help of printed circuit design software. Once you’ve made the board layout, draw the board. Transfer your circuit’s design schematics on to your prototype. Draw circuit boards using the design guidelines. Furthermore, you can use free PCB software to draw your board.

In order to create your own printed circuit board prototype, you must consider a few important things. First and foremost you must decide whether you’ll put the circuit in a box. Secondly, you need to keep in mind that in order to fit the tall components you’ll need to lay them down flat. Furthermore, you should print out the drawing of your components only after you’ve placed them on your board.

Lastly, you’ll need to utilize the paper version of your board to test whether your connectors will fit and if the board will fit the box. Once you’ve drawn the board, you’ll need to prepare the printed circuit board design for manufacturing. In simple terms, you’ll have to check:

- The prototype for errors

- The layout of your board to Gerber files

Once you’ve done that, you can get your printed circuit board prototype manufactured by engaging the service of a cheap prototype PCB manufacturer. There you have it—your own cheap printed circuit board prototype.