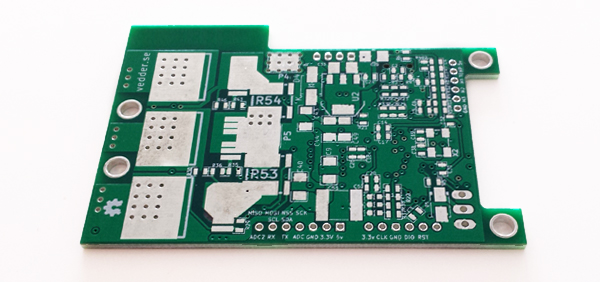

Understanding 4 layer PCB prototype and its fabrication process

Today, you’ll find information about prototype Printed circuit boards that range from simple double-sided PCB prototypes to PCB prototypes with over thirty layers. Made up of four electrical layers laid on each other, 4 layer PCB prototype is one such prototype circuit board. Resin layers called prepreg are used to bond the copper layers together. 4 layer PCB prototype is a cheap PCB prototype option. This is the reason they’re in high demand. There are many manufacturing that offer 4 layer PCB (link article 13) prototype fabrication services. However, to manufacture this cheap PCB prototype they’ll require certain files including:

• Profile layer file

• Top and bottom silkscreen

• CNC drill files

• Top and bottom Soldermask

• Top, inner 1, inner 2, and bottom copper

The 4-layer printed circuit board prototype fabrication process involves the use of certain materials. Following are some of them.

Copper

For electrical diagrams, copper is the basic material

Core

To make inner double-sided, a circuit frame covered with copper on both sides is used. This circuit frame is known as core.

Prepreg

Used for insulation and adhesion, prepreg is a vital multi-layer boar part

Solder mask

Solder mask is used for a variety of purposes including insulation, avoiding welding and avoiding corrosion.

Legend

It is used for highlighting purposes

Surface finishing materials

In order to enhance the appearance of 4-layer printed circuit board and protect its components from atmospheric effects, surface materials such as silver, immersion gold, or immersion tin are used.

The 4-layer printed circuit board prototype fabrication process involves the following steps:

• Front-end tool data Preparation

• Etching the inner layers with a powerful alkaline solution

• Aligning the inner layers to the outer layers by punching in the required holes

• Bonding all the layers together

• Drilling the printed circuit board including drilling holes for leaded components as well as the holes that connect the copper layer together

• Soldering

• Final testing

• Inspection

There are many benefits of using a PCB prototype manufacturer to get your 4-layer printed circuit board made. The first of these benefits is the quick delivery of your 4-layer PCB prototypes. The second and most important of these benefits is the economical price of the PCBs. With these PCB prototype manufacturers, you can start prototyping PCBs for less than $ 40 per piece. Furthermore, these manufacturers offer great discounts for higher-production volumes. Apart from the aforementioned benefits, there are some other benefits of using a PCB prototype manufacturer including:

• In order to better meet your real demands, the manufacturers offer multiple quantity choices

• Production of all PCB prototypes is done using their proven standard processes.

• Thickness and color choices

• Completely free E-test

4-layer printed circuit board prototypes are used by many different fields including medical, consumption products, telecommunication, and security. There are many benefits of using a PCB prototype manufacturer to manufacture your 4-layer printed circuit board prototype. Cheap PCB prototype is one of them.