Reasons to use a Fast PCB Prototype

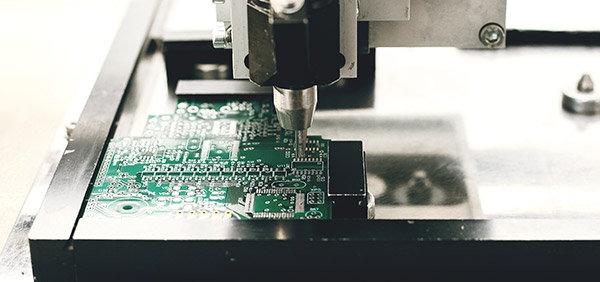

Today, every person in the world is striving hard to save time, energy, and money. This includes customers of printed circuit boards. A great way for customers of printed circuit boards to save, time, energy, and money is using a PCB prototype. A sample PCB based on the original PCB pattern, PCB prototype is used to reduce the chances of failure after production and facilitate the process of inspection.

Prior to going through with a full printed circuit board production run, manufacturing a PCB prototype and performing various tests on it is recommended. Additionally, making prototypes to the highest specification possible is crucial. A critical part of PCB prototyping is lead-time because it provides you the ability to test out your prototypes at a faster rate than your competition. Therefore, having an agile manufacturing process in place to produce PCB prototypes is important. A great way to test out prototypes at a faster rate than your competition is fast PCB prototype.

The need to assemble models of printed circuit boards within a strict time deadline before they’re put into final fabrication process is what gave birth to the concept of fast PCB prototypes. Quick turn PCB helps companies to get a faster turnaround time which in turn allows them to prototype their critical PCBs faster. Experts who’ve mastered the technique of creating cost effective faster turnarounds make these PCB services available to customers. However, before opting for fast PCB prototype you must consider the exact PCB requirements. You must ensure that your specific needs are met by the specifications and benefits offered by the quick turn PCB prototype service provider.

There are many benefits of using the aforementioned PCB prototype. This includes increasing your return on investment by decreasing the probability for poor printed circuit boards. There are many manufacturers out there that can help you to achieve this. All of have to do is send them your Gerber files and they’ll take care of the rest. Using the same materials, processes, and equipment used to manufacture mass production PCBs, these manufacturers build your PCB prototype. Furthermore, you can expect a high level of quality even though this is a cost effective solution.

Build to your specifications, these prototypes meet the requirements that you may have for a high quality and completely functional printed circuit board. Following are the reasons you should opt for a fast PCB prototype service:

• Since you’re able to check PCB design before placing the order, you can prevent unnecessary delays. Furthermore, waiting for clarification process and design verification isn’t a necessity.

• Prompt and personal assistance from one of the technicians or engineers who help you with the design specifications

• Quick assembling of printed circuit board prototype according to your design specifications

By using the aforementioned prototype, you can enhance your production a capabilities. Furthermore, you can test your critical prototypes faster which in turn will help you to decrease the probability for poor printed circuit boards and increase ROI.