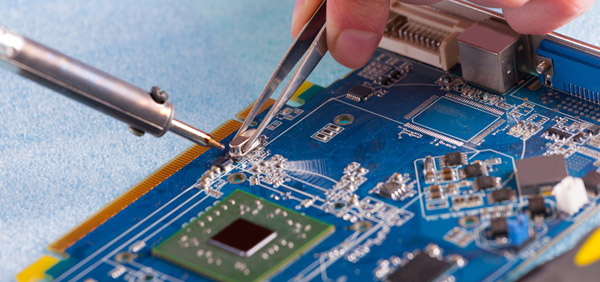

Circuitry Repair

All our day to day electronic devices along with heavy industrial machinery contain circuit boards. This is why circuitry repair is such a big part of life nowadays since everyone is addicted to their laptops and other electronic devices and a damaged circuit board can really put things in halt mode.

Soldering And Related Problems

Most of the time circuit repair means mending soldering joints that have cracked due to high heat pressure or other miscellaneous causes.

• A disturbed joint is very common in household repairs done by the homeowners themselves because it simply means they did not let the glue or similar material fixate properly while they were soldering. A slight movement during the process of drying means impaired electrical connectivity for later.

• Cold joints are also characteristic of amateur work as it means that the joint was not fully melted so there might be unsightly lumps on the surface of the circuit board. If you are attempting soldering at home, make sure you are using an iron which is fully heated. These also cause problems with circuit functionality.

• When the circuit board overheats it can crack and also damage the solder joint and cause a buildup of flux which is difficult to get rid of unless you are willing to invest in something like a conductor pen or a small drill with a pointed end.

• Pads are a removable part of the circuit board and are often the first places where signs of excessive use begin to show. It is really inexpensive to replace them and this can be done at home with some bought in packs from the hardware store.

• If too much solder has been poured into the board, this can also cut off the connection or prevent the establishment of a reliable connection so you can drill or chip the excess off (you might need to heat it up slightly) and aim for a more smooth surface top to the board.

• Good wiring is the key to a fully functioning and efficient circuit board and you need to check all wires and leads periodically as they can tarnish and rust with time or if moisture is allowed to accumulate around them. Make sure that the leads are not too long and dangly once they are protruding out of a well-made solder joint. If they are too long, trim them before attaching them again.

• It sometimes happens that a pad rises from the board since it wasn’t stuck down or screwed into the board properly. This can also cause short circuiting.

• For all the above you need a light hand and the proper tools like a small drill, a pointed soldering iron, clamps to hold the components while they dry and some good old epoxy super glue for a flawless finish.

Furthermore, keep your circuit protected from the elements like water, excessive sunlight and so on. If you find that your circuit is not working it may simply be because of moisture in the air or on the board itself which causes various components to rust and oxidize.